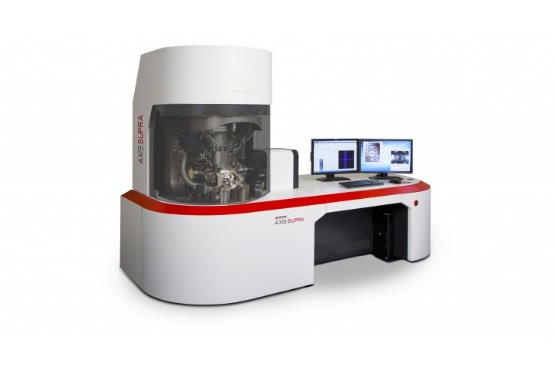

The spectroscopic and imaging performance of an X-ray photoelectron spectrometer define its ability to perform in the most demanding research and development laboratories. The AXIS Supra excels at both and combines the highest level of automation currently available with the flexibility to incorporate complementary surface analytical techniques. Designed for ease of use with automated sample loading and exchange, integrated camera system, easy to use ESCApe data acquisition and processing software, the AXIS Supra really is made to measure.

Capabilities of the AXIS Supra

LARGE AREA, HIGH SENSITIVITY XPS

The AXIS Supra is first and foremost a high performance X-ray photoelectron spectrometer. Efficient collection of photoelectrons by the magnetic and electrostatic lenses combined with the high transmission 165 mm mean radius hemispherical analyser ensures that the AXIS Supra has unrivalled sensitivity and resolution.Spectra are collected in traditional scanned mode or fast, unscanned snap-shot mode where spectra may be acquired in less than a second using the delay-line detector (DLD).

Key attributes include:

• Easy detection of light elements.

• Excellent signal-to-noise, even at low concentrations.

• Fast data acquisition

SMALL SPOT, SELECTED AREA SPECTROSCOPY

Selected area spectroscopy is achieved by inserting a motorised aperture into the electrostatic lens column, forming a virtual probe at the sample surface. This approach means that selected area spectroscopy can be performed with either the monochromatic or achromatic dual anode X-ray source. Spectra are acquired from pre-defined analysis areas as small as 15 μm diameter from any position within the field of view of the lens. Key attributes include;

• Pre-defined small spot analysis areas.

• Optimised x-ray illumination for selected area performance.

• Click and analyse multipoint spectroscopy without sample movement.

HIGH ENERGY RESOLUTION

The primary application of the AXIS Supra is as a photoelectron spectrometer for chemical statecharacterisation of the surface. The 500 mm Rowland circle monochromated Al Ka X-ray source and optimised electron optics contribute to the excellent energy resolution performance.

• Unambiguous identification of chemical shifts.

• Guaranteed energy resolution on insulating and conducting samples.

FAST PARALLEL IMAGING

Parallel imaging, where an image of the sample surface is projected via the unique spherical mirror analyser (SMA) onto the 2D delay-line detector, allows the lateral distribution on surface chemistry to be investigated. Fast parallel imaging produces images with higher spatial resolution than the more traditional mapping approach.

• Ultimate spatial resolution of 1 μm at the highest magnification.

• Simple mouse click on image to define area of interest for selected area spectroscopy.

• Stitched imaging – combining parallel images with stage movements allows high spatial resolution images to be acquired over areas of several millimetres.

• Quantitative imaging – the unique SMA operates in fixed analyser transmission which ensures that energy resolution is constant as a function of kinetic energy allowing quantitative chemical state imaging.

• Spectromicroscopy – easy acquisition of spectra from images where a series of images are acquired over a defined energy range to produce a spectrum at each pixel.

UNRIVALLED INSTRUMENT AUTOMATION

Complete automation sets the AXIS Supra apart from any other X-ray photoelectron spectrometer currently available. Unattended sample transfer and exchange during analysis is realised through coordination of the Flexi-lock sample magazine and autostage in the sample analysis chamber. Auto exchange of sample holders during analysis ensures extremely high sample throughput removing the rate-limiting step previously associated with sample loading. Motorisation of both X-ray source and X-ray mirror automates calibration. Switching between monochromated Al Ka and the optional Ag La excitation sources is under full computer control. Where gas introduction to the vacuum system is required such as ion etching or UPS, gas handling and pressure regulation is fully automated. Automation extends to data interpretation with auto-peak ID integrated into the ESCApe processing software.

• Automated sample introduction and exchange.

• Computer controlled X-ray source and mirror.

• Automated gas introduction and pressure regulation for ion sources and UV lamp.