The SMV-301 / 301RT allows the user to measure the Mooney viscosity, scorch time, minimum Mooney viscosity, and other characteristics of rubber in accordance with JIS, ISO, and ASTM test methods. With outstanding temperature recovery characteristics and easy operability, it can also be used for stress relaxation measurements or for tests that involve varying the rotor speed.

Max. 200 M Capacity (or optional 400 M capacity) The automatic calibration unit (optional) allows weights to be automatically calibrated to ensure high testing reliability.

A V-groove die compliant with JIS, ISO, and ASTM standards ensures tests can be performed in accordance with global standards.

Torque can be calibrated easily via the touch panel by calibrating weights using the automatic weight calibration unit (optional). The ability to perform routine sensitivity calibration electronically via the touch panel ensures highly reliable routine testing.

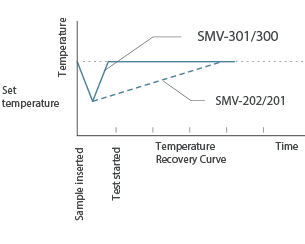

Excellent thermal stability and temperature recovery characteristics enable high reproducibility.

Optimal control and film heater units provide shorter temperature recovery times after inserting specimens and, due to the highly stable temperature control system, highly reproducible test results.

Also supports stress relaxation testing, cycle testing,

and variable rotor speed testing.

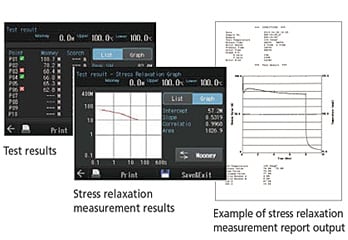

The SMV-301RT can also measure stress relaxation and decay in accordance with ISO 289-4 and ASTM D 1646. In addition, the difference in viscosity between samples can be determined more easily by using multiple rotor speeds (between 0.1 and 20 rpm) during testing to evaluate mixing or by varying the strain level. Performing various tests in that manner allows viscoelasticity of rubber samples to be evaluated.

Simple Cleaning and High Safety Improve Testing Efficiency

A windbreaker casing is also included standard.

The auto-start function is linked to the casing to improve both safety and efficiency.

The casing prevents external disturbances from the surrounding temperatures during measurements and prevents temperature variations around the die. An interlock mechanism prevents the crosshead from ascending or descending except when the casing door is closed. The viscometer also includes an auto-start function that can automatically start tests when the casing door is closed while in the standby mode. These functions help ensure that tests can be performed efficiently and safely.

Installing an optional display tower signals a warning to surrounding personnel.

The rotor lifting function makes cleaning easier.

Mooney viscosity testing requires cleaning the die and rotor after each test. Because the surface of SMV-301/301RT rotors is treated to prevent sticking to samples, while also maintaining adequate rotor hardness, samples are much easier to peel off of the rotor after tests. The rotor lifting function also makes it easier to remove the rotor after tests.

A warm-up function provides a smoother test starting process.

This function automatically warms up the system to a specified temperature, so that it is ready to start testing at the specified time.

It also allows saving and loading test conditions, thereby improving the efficiency of testing using multiple different conditions.

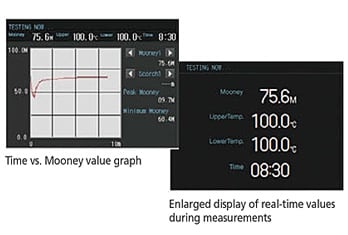

A Color LCD Touch Panel Improves Testing Efficiency by Improving Testing Operations

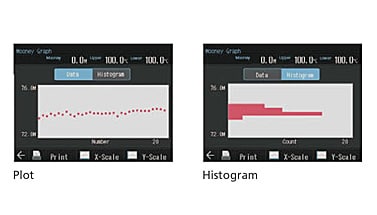

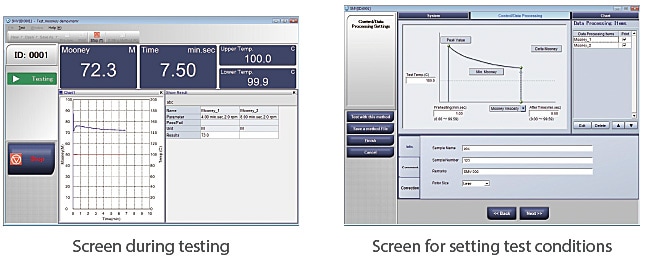

A color LCD touch panel makes it easy to specify test conditions. It also includes extensive data analysis functionality, such as for displaying results, performing statistical calculations, editing data, and displaying graphs.

- Creating and Loading Test Conditions

All test conditions can be set via the screen.

Saved test conditions can be loaded from a file. Up to 10 values can be specified for Mooney viscosity detection time, rotation speed (on RT models), or scorch point settings. Mooney viscosity values can be used for automatic pass/fail decisions as well.

- Start Test ⇒ Preheat ⇒ Test

The auto-start function automatically lowers the crosshead and starts preheating as soon as the windbreaker casing is closed. After preheating, it automatically starts the test. If multiple measurement conditions are set, in addition to displaying results when the test is finished, interim results for each setting can be displayed at any time during measurements.

- Display Results, Print Reports, or Output Data

After testing is finished, Mooney viscosity criteria specified in advance or pass/fail results based on those criteria can be displayed, and a logarithmic graph of scorch time or stress relaxation measurements can be plotted automatically. Test results can be printed out directly from the touch panel (printer is optional).

- Statistical Processing

All data with the same sample number in test conditions can be processed as one file for statistical processing. Saved test results can be displayed, statistical data plotted, or histograms created.

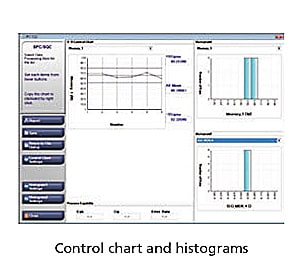

PC Software Improves Testing Efficiency

The SMV-301/301RT models make it possible to set test conditions, display data in real time, and acquire, save, analyze, or statistically process data using computer software. Furthermore, up to four SMV-301/SMV-301RT Mooney viscometers can be controlled from one PC for more efficient testing.*

* Multiple units cannot be controlled in combination with an SMV-300 model.

Up to 4 instruments can be controlled with a single PC

Smooth Process from Creating Test Conditions to Statistical Processing of Test Results

<Main Specifications>

- Display real-time data during tests.

- Display real-time graphs of time vs. Mooney value or time vs. temperature.

- Control up to four Mooney viscometer units connected to the computer.

- Specify test conditions, display results after tests, determine pass/fail results, overlay graphs, and output data for data analysis.

- Statistical processing, such as calculating average values and standard deviations and plotting graphs and histograms

- Integrating software for displaying the connection and operating status and ID codes of respective instrument

- Change test conditions from the viscometer unit.

- USB 2.0 communication interface with the PC

Recalculating, Overlaying, or Statistically Processing Test Results Is Easy

When the viscometer connects to the software, it waits in standby mode using the previous test conditions settings, which means tests can be performed consecutively without having to change test conditions.

Saved test results and data can be displayed or control charts created from the data, such as graphs or histograms.

Varied Rotor Speed in Cycle Tests for Mooney Viscosity and Stress Relaxation (SMV-301RT)

Multiple cycles of combined Mooney viscosity test and stress relaxation measurements can be specified (total measurement time: max. 30 minutes).