Advanced Operability and Ultimate Image Quality That Overturns Conventional Assumptions inspeXio SMX-225CT FPD HR Plus The inspeXio SMX-225CT FPD HR Plus is a high-performance microfocus X-ray CT system equipped with a Shimadzu microfocus X-ray generator and a large high-resolution flat panel detector. The large detection area, input resolution equivalent to 14 megapixels, and an enhanced high-output microfocus X-ray generator enable CT images with a large field-of-view, high resolution, and high contrast. In addition, the improved HPC inspeXio high-performance computing system processes images faster. These developments make the inspeXio SMX-225CT FPD HR Plus system applicable for researching, developing, or inspecting a wide variety of samples, from composite materials, such as glass fiber reinforced plastic (GFRP) and continuous fiber reinforced thermoplastic laminate (CFRTP) materials to large aluminum die cast parts. *System Configuration and Operating Principle.

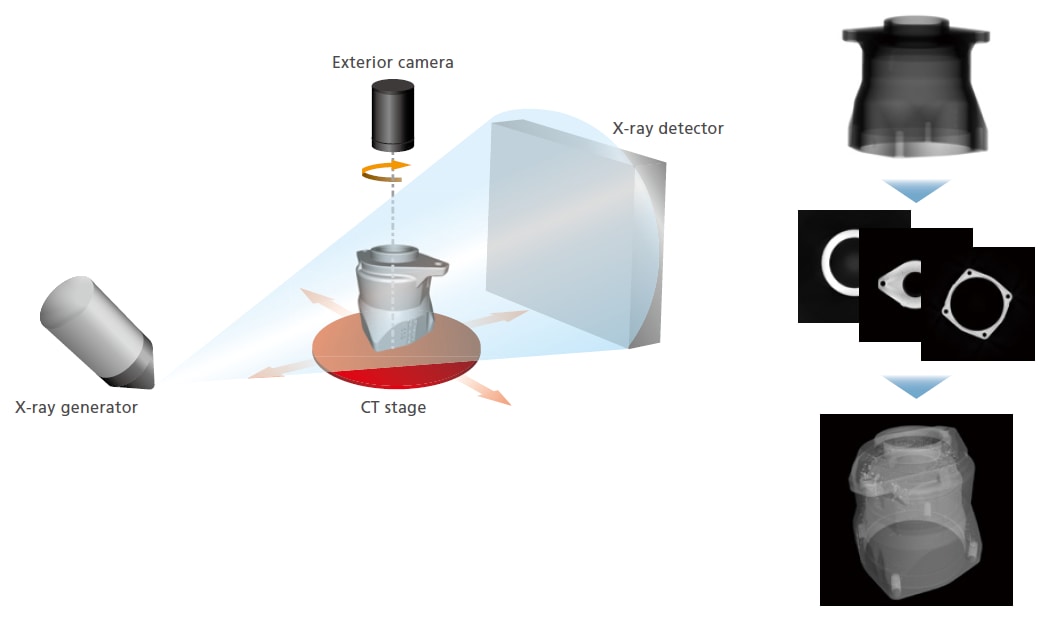

System Configuration and Operating Principle

The inspection target (sample) is placed between the X-ray generator and detector, as shown below. Then, the sample is rotated 360 degrees to collect X-ray fluoroscopic data from various angles in order to calculate cross-sectional images.

High-Resolution CT Image

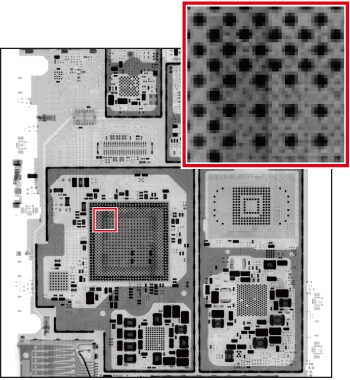

Maximum 14 Megapixel Input Resolution

The large high-resolution flat panel detector achieves an offset scan input resolution of up to 14 megapixel.

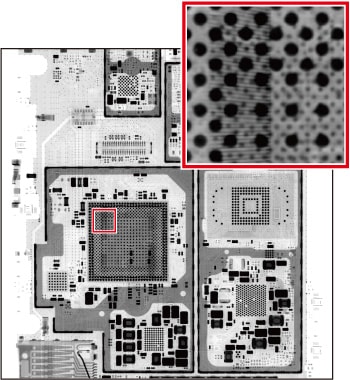

Low-Resolution Transmission Image (1,000,000 pixels)

High-Resolution Transmission Image

Low-Resolution Cross-Sectional Image

High-Resolution Cross-Sectional Image(14 Megapixel Input Resolution)

4,096 × 4,096 Pixel Cone-Beam CT Reconstruction

Supporting cone-beam CT reconstruction with an ultra-high resolution of 4,096 × 4,096 pixels, the system can fully utilize the performance of the high-resolution X-ray detector.

High-Contrast CT Image

Improvements to the Shimadzu-made microfocus X-ray generator and the sensitivity characteristics of the state-of-the-art flat panel detector enable unprecedented high output and image contrast.

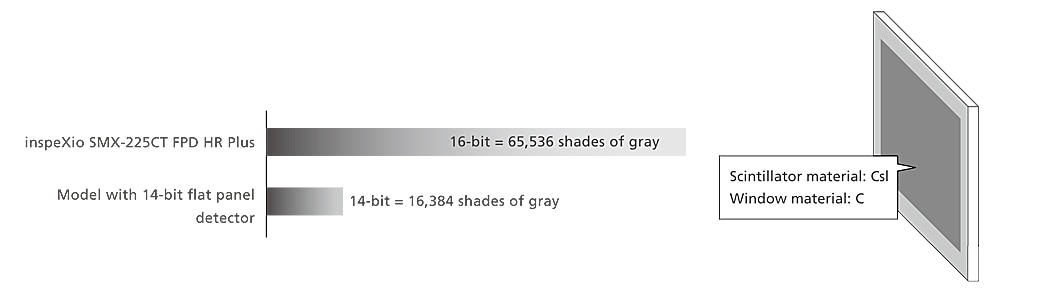

High-Contrast Detector with Wide Dynamic Range

Cesium iodide (CsI), which has excellent sensitivity characteristics in the long wavelength region, is employed as the scintillator material.

The use of carbon (C) for the detector window material enables imaging on low-density materials. Furthermore, the wide dynamic range (16-bits) enables small contrast differences to be displayed.

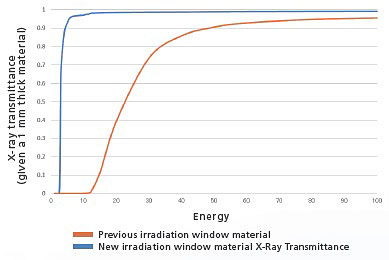

Improved X-Ray Generator

The Shimadzu-made microfocus X-ray generator unit now includes a newly developed irradiation window. Due to the larger proportion of soft X-rays in the X-ray output, it offers significantly improved contrast when scanning low-density materials that easily transmit X-rays.

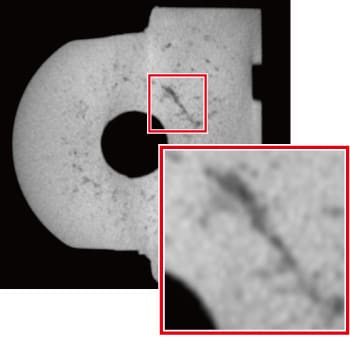

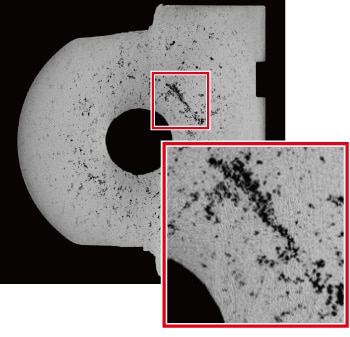

Comparison of Transmission Images from Non-Woven Fabric

Previous Cross-Sectional Image

New System Cross-Sectional Image

Easy and Fast CT Scan

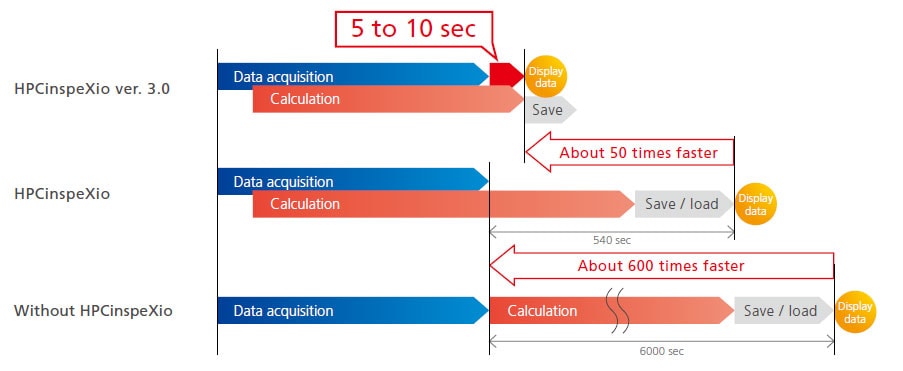

In addition to the automated CT scanning function, which relieves the operator from having to specify parameter settings, the system also includes an improved version of the HPC inspeXio ver. 3.0 high-performance computing system, providing 50 times faster processing speeds.

Intuitive User Interface

The new user interface features a simpler arrangement for intuitive operation.

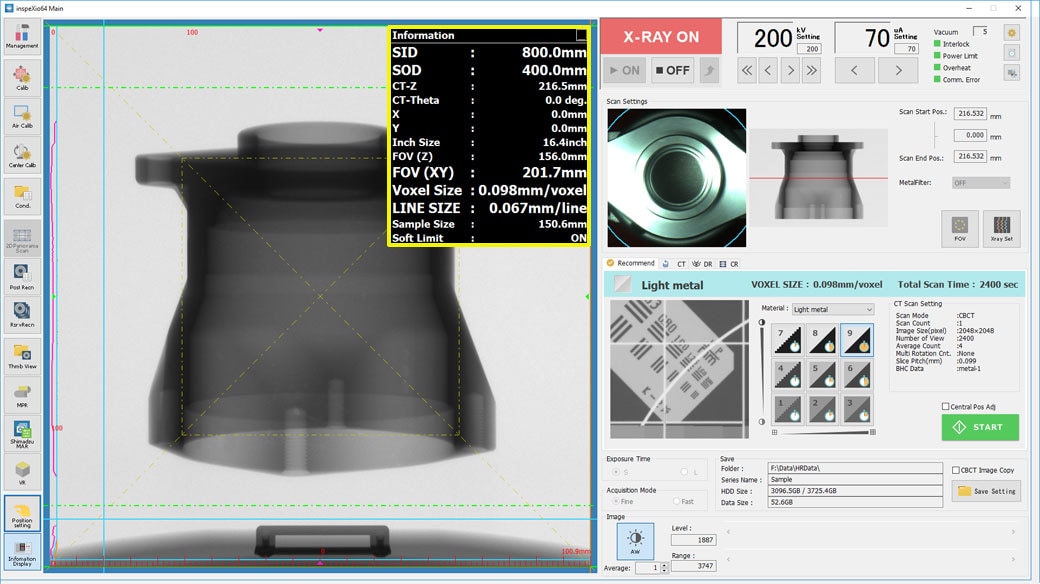

Main System Window

Displays the stage position, scan field of view, equivalent voxel length, and other information in real time, making (the yellow box),it easy to scan images with the specified resolution and field-of-view size.

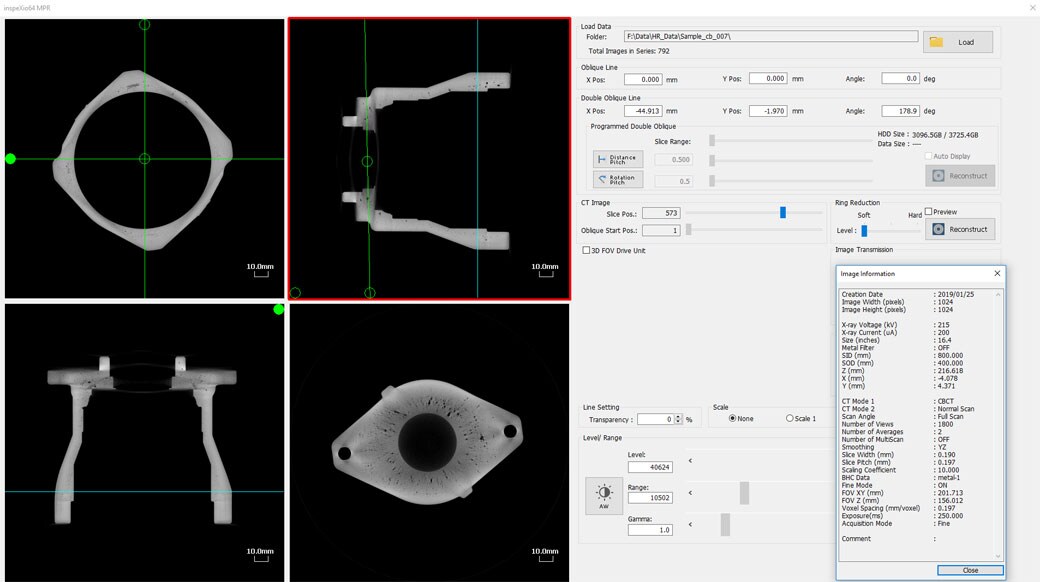

MPR Window

Displays slice, oblique, and double-oblique images, enabling the easy observation of cross-sections.

Automated CT Scanning Function

The new automated CT scanning function enables scan parameters to be specified easily.

Simply select the material, the desired CT image resolution, and the contrast level, and the system automatically optimizes the CT scanning parameter settings accordingly.

HPC inspeXio High-Performance Computing System ver. 3.0 New!

The new HPC inspeXio high-performance computing system is around 50 times faster* than the previous version.

* When the fast acquisition mode is configured and the CT image size is set to 1,024 × 1,024 pixels

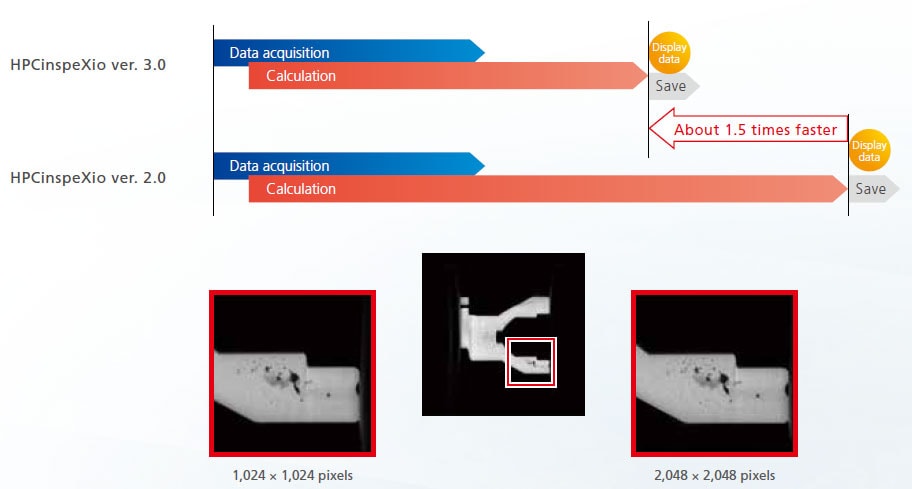

Even Faster 2,048 × 2,048 Pixel Cone-Beam CT Reconstruction New!

The high-performance computing system is updated. The processing time for 2,048 × 2,048 pixels Cone-Beam CT reconstruction* is around 1.5 times faster than the previous version.

* Setting conditions: “Clear”, 1200View, full scan, AUTO scaling factor, reconfiguration (2,048 × 2,048 pixels)

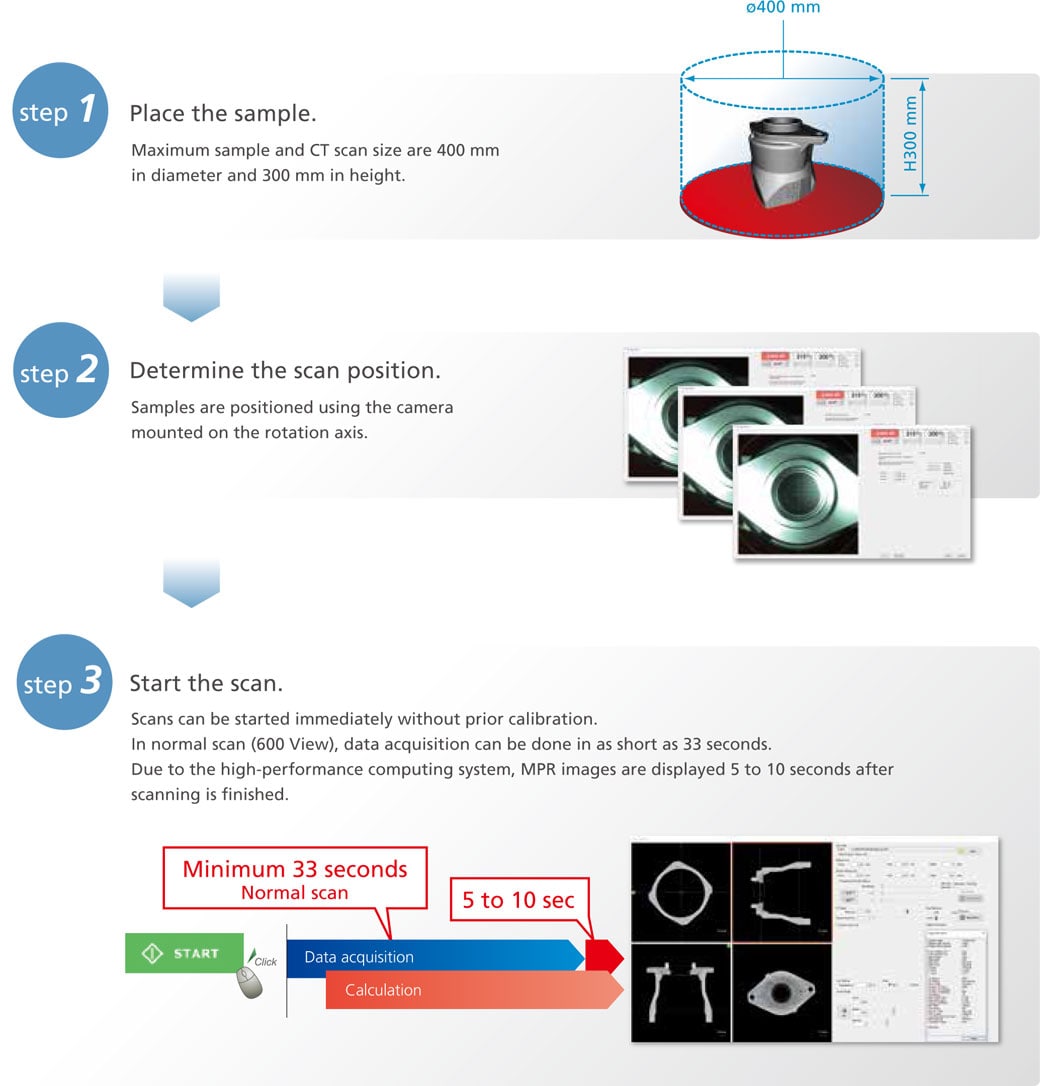

Obtain CT Images in Three Easy Steps

No calibration process is necessary before scanning. Scans can be started immediately after sample placement.

3D CT Scan Region Display Function

As the CT stage moves, the corresponding CT scan region is displayed, overlaid in realtime on the MPR display.

Based on the previous CT scan image, additional CT scans for areas of interest can be obtained.

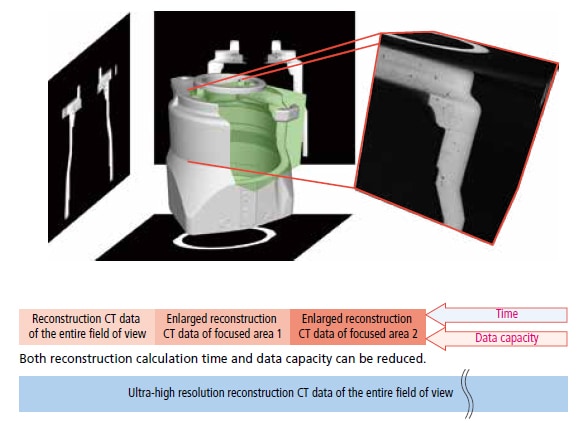

Advanced 3D image Reconstruction New!

It is possible to enlarge only the focused areas in images once acquired and perform the reconstruction calculation. High-magnification cross-sectional images can be obtained even in the works that enlargement ratio is difficult to be improved. Equipped with a high-resolution flat panel detector, clear cross-sectional images can be obtained even when performing reconstruction. It is not necessary to perform the CT scanning once again when performing reconstruction only.