- Easy optimization of preparative parameters and scale up

Fractionation simulation for rapid setup of collection logic Column line-up for scale-up from analytical to preparative - Time- and energy-saving by automation of the purification workflow

Collection of target components at high purity by automated desalting - Expandable to suit the sample/fraction number and volume

Choose from a wide range of options for recovery scale and analytical detection Problems are resolved simply, to accommodate a variety of needs.

Streamline and Simplify Establishing the Conditions for Preparative Work

Nexera Prep System

Streamline development of Analysis Conditions and Optimization of Preparative Parameters

In order to separate multiple components, the analysis and fractionation parameters must be optimized, which involves a great deal of work.

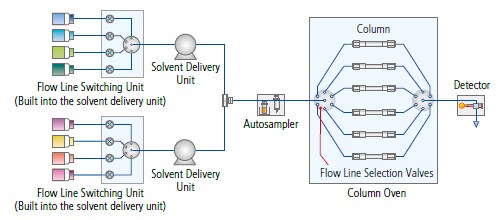

Shimadzu provides the Method Scouting system, which investigates conditions at the analytical level. Method Scouting system fully automates method scouting in which combinations of mobile phases and columns are automatically changed, equilibrated, and evaluated, allowing efficient method development.

Further, the preparative system performs automatic simulations using the pre-preparative results, enabling optimization of the fractionation parameters.

This reduces the work involved in investigating conditions, which saves on mobile phase solvent and samples.

Development of Analytical Conditions (Method Scouting System)

A development is performed to separate the target compounds at the analysis level.

Using the Shimadzu Method Scouting system together with Method Scouting Solution, a special software program, provides a fast and accurate method scouting workflow, which supports heightened efficiency in method development.

Significantly Reduces the Process of Setting Fractionation Parameters

Simple parameter setting by fraction simulator

LabSolutions™ software provides simulation functions that reduce the labor involved in investigating conditions for analytical and preparative work.

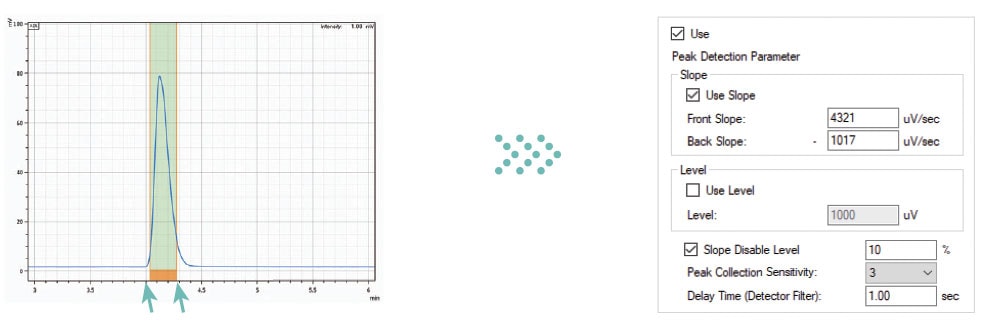

With the LabSolutions fractionation simulator (patent pending), specify the peak segment in the chromatogram to fractionate, and the system automatically sets the parameters required for fractionation. This reduces the time spent on setting fractionation conditions to about 1/4 the typical expenditure.

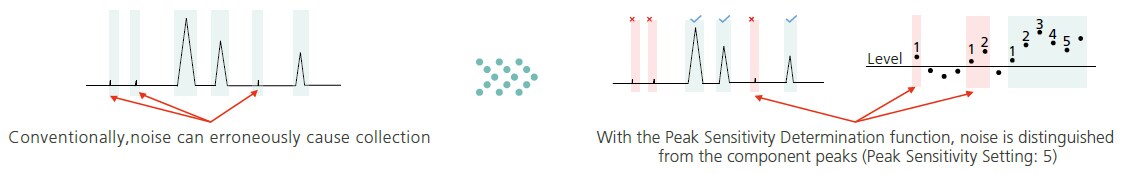

Noise skipping by new algorithm

When configuring fractionation via automatic peak recognition, noise in the chromatogram is sometimes mistaken for component peaks, resulting in an insufficient number of test tubes for intended collection or improper positioning of collected fractions. With the LabSolutions software Peak Sensitivity Determination function (patent pending), peaks are recognized from the number of data points consecutively exceeding the configured threshold value, to determine whether to fractionate.

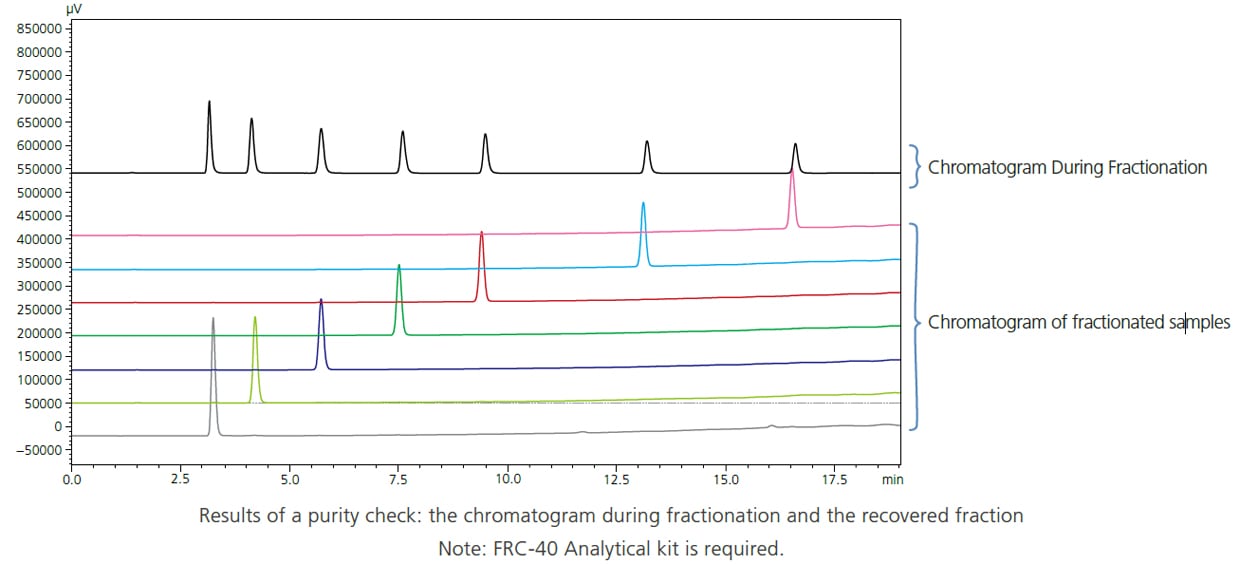

Fraction Purity Checks(LH-40)

A fraction purity check can easily be performed with a single system. Purity checks can be performed without changing the fraction recovery container, so the workload is reduced and throughput is improved.

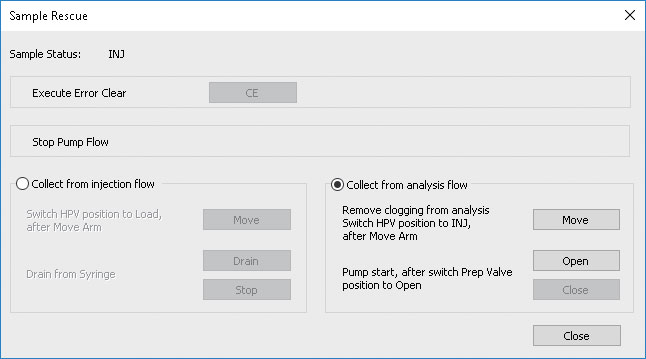

Sample Rescue Function Prevents the Loss of Precious Samples (LH-40, FRC-40)

Even if a problem occurs during preparative work, the sample remaining in the system can be recovered. By following the rescue instructions, the precious sample is recovered into the specified container rather than being discarded. Additionally, by using the optional waste collector, samples that cannot be recovered due to fractionation mistakes can be retained.

Preparative Work for Target Components at High Purity Levels and High Concentrations

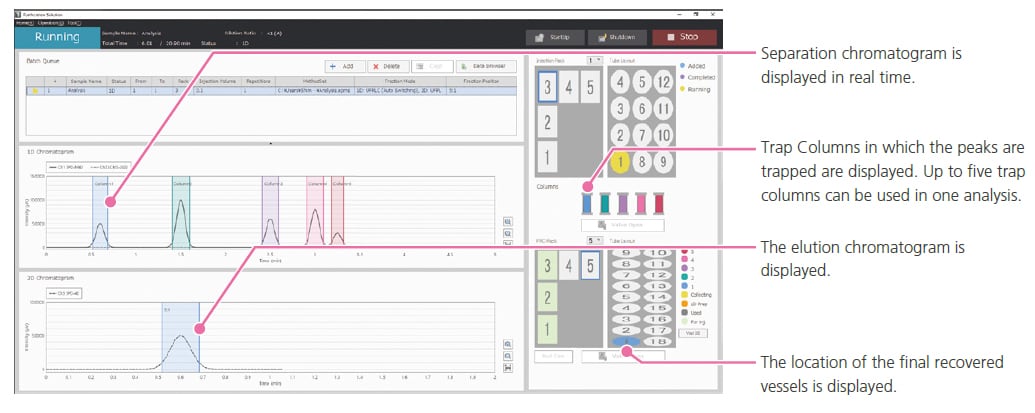

Equipped with Technology for the Trap Enrichment of Target Components

Nexera UFPLC, Ultra Fast Preparative and Purification Liquid Chromatograph System

Significantly Reduces the Processes Involved from Preparative Work to Purification (Free basing Treatment) and Powderization

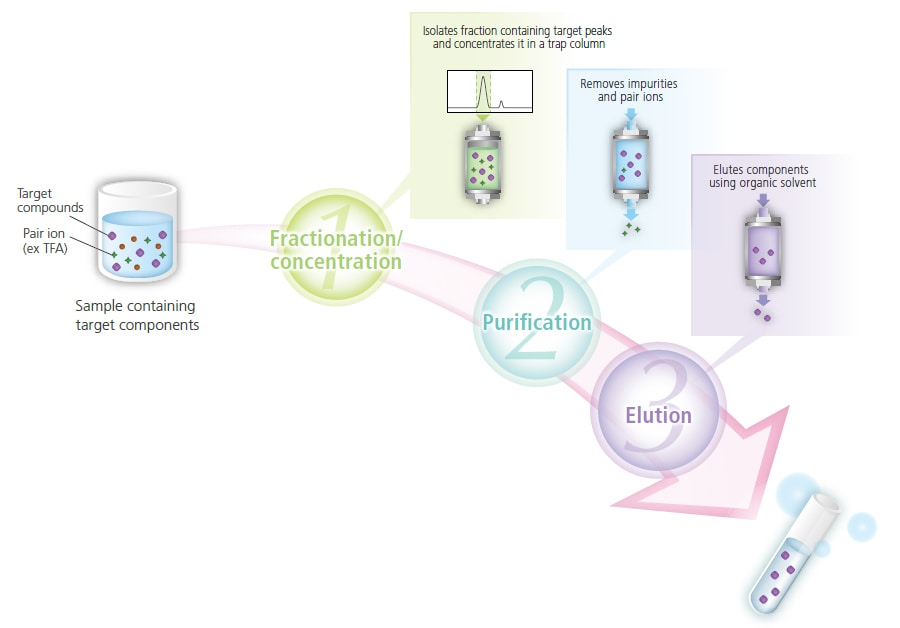

The ultra fast preparative and purification liquid chromatograph system, Nexera UFPLC, streamlines purification operations by automating the preparative process from separation to concentration, purification, and collection.

In conventional preparative LC, the amount of fraction is diluted with the mobile phase, resulting in a huge volume, which takes time to evaporate, and post-treatment work, such as removal of salts derived from the mobile phase, is required. Nexera UFPLC concentrates target components by using a trap column. In addition, salts derived from the mobile phase and counter ions of the target compound are removed. Furthermore, because organic solvents are used to elute the target components,the time for evaporation can be significantly reduced.

Nexera UFPLC can also be used for standard preparative chromatography by collecting the fractions directly without any concentration steps.

Automation of the Preparative Purification Process

When target compounds are to be powderized, this process can be hindered by a number of factors including the presence of acids, salts, and refractory solvents. With the UFPLC Ultra Fast Preparative and Purification Liquid Chromatograph, these hindrances to powderization can be removed by flushing them out using a trap column, allowing a high purity powder of the target component to easily be obtained by anyone.

Even Trace Components Are Recovered at High Concentrations

Normally, when preparing trace quantity target components, preparative work involves injecting the sample multiple times to obtain sufficient amounts of the target. As a result, the volume of fractionation liquid ultimately obtained increases in proportion to the number of injections, increasing solvent use and dry down time. With the UFPLC Ultra Fast Preparative and Purification Liquid Chromatograph, even with multiple injections, the fraction of the target component is injected into the same trap column for enrichment. The final volume of fractionated liquid from the trap column is minimized, exchanging the weaker loading solvent for a suitable organic solvent. The target component can then be recovered at high purity levels and at high concentrations.

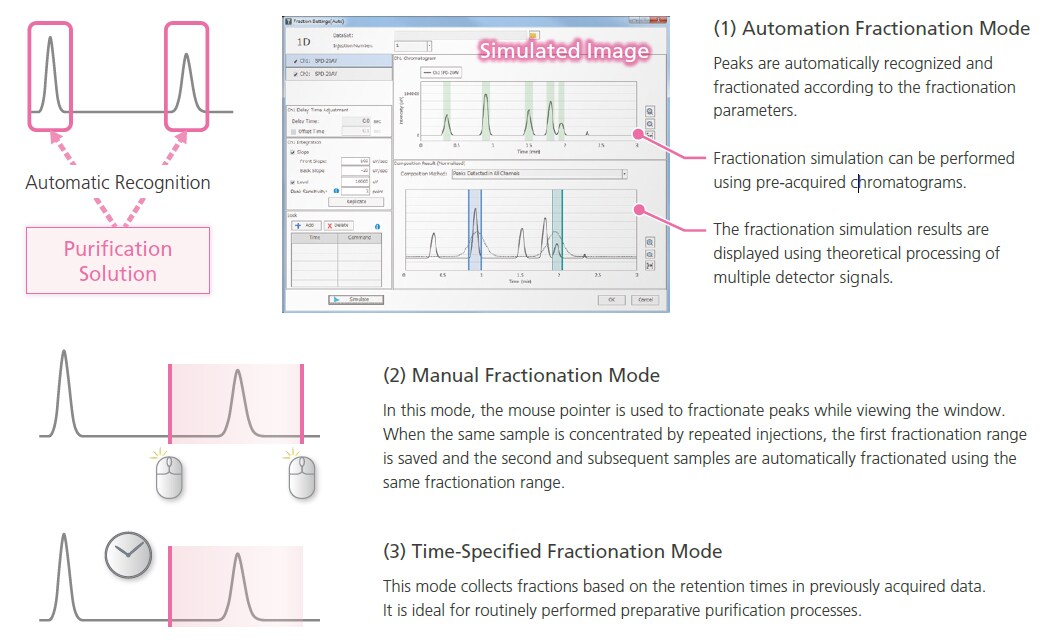

Purification Solution™ Simplifies Settings Related to Preparative Purification

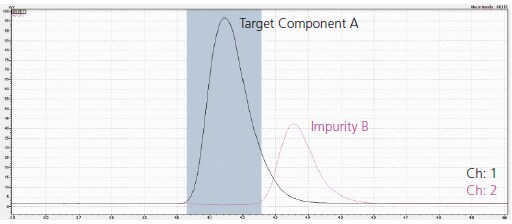

The special Purification Solution software is equipped with peak tracking functions that enable the target peaks and fractionate and be checked at a glance.

Various Fractionation Modes

To ensure that valuable samples are fractionated, Purification Solution offers three fractionation modes.

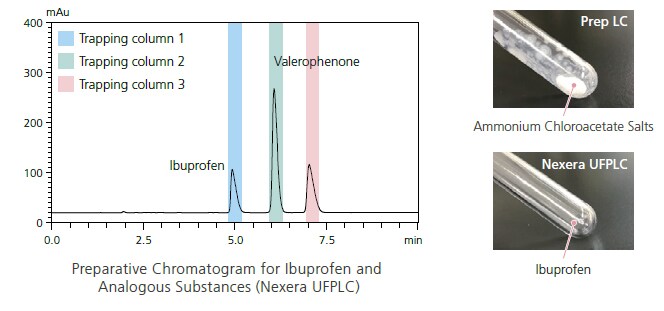

Automatic Removal of Non-volatile Salts

In the conventional preparative LC, salts derived from the mobile phase are included in the recovered product. With Nexera UFPLC, salts derived from the mobile phase can be removed on the trap column.

In the picture below, Ibuprofen was prepared using a solvent containing ammonium chloroacetate, a non-volatile salt. With conventional preparative LC, ammonium chloroacetate precipitated at the same time during evaporation. However, ibuprofen was recovered as a single component with Nexera UFPLC due to the use of a trap column.

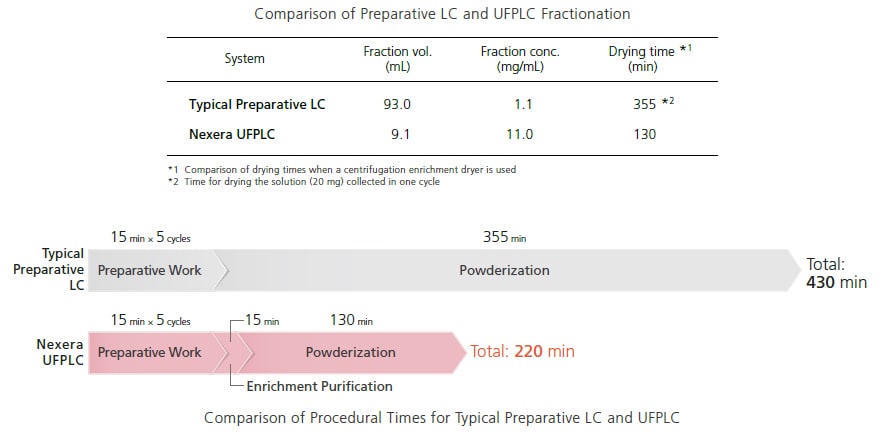

Concentration and Powdering of Target Ingredients in a Short Period of Time

Using Nexera UFPLC, samples are repeatedly injected and the target components are introduced into the same trap column, allowing concentration on the trap column (up to 100 mg capacity). After concentration, the target component is eluted with an organic solvent, allowing recovery of the target component at a high concentration and shortening the time for evaporation. The volume of recovered liquid and the time required for evaporation were measured when 100 mg of the target component, ibuprofen, was purified by trap purification. Compared to the conventional preparative LC process, the overall time was reduced by 50%.

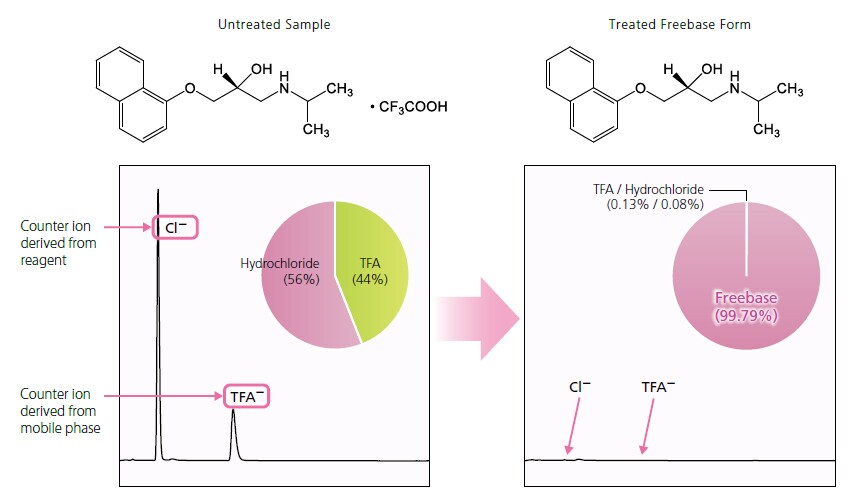

Counter Ions Removal

In some cases, basic compounds can contain counter ions (such as trifluoroacetic acid, TFA) derived from both reagent and mobile phase. These components may remain as impurities, affecting the final purity. With Nexera UFPLC, the target component can be recovered as a high-purity free base (free base type) by using a trap column.

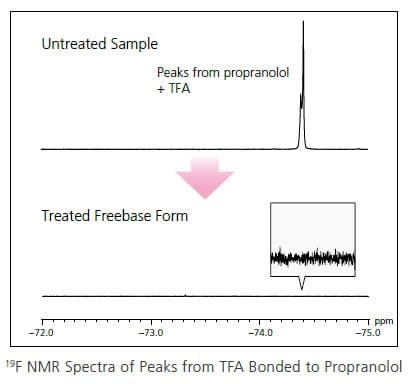

Structural Analysis without Preprocessing

The 19F NMR spectrum of a 0.1% TFA solution containing propranolol after freebasing treatment is shown. Compared to the untreated sample, the TFA-derived peak in the fractionated sample is significantly smaller, confirming that TFA is effectively removed in the purification process using Nexera UFPLC.

Preparative Work for Non-UV Absorptive Components

Capable of High Purity Preparation Triggered by up to Four Detector Channel Signals

Nexera Prep LC/MS Preparative System

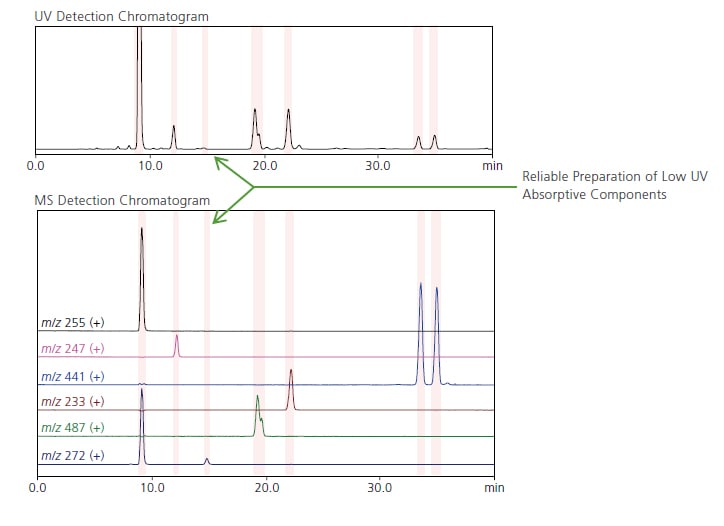

Using MS Signal Triggers Enables Recovery with no Target Fraction Omissions

It can be difficult to prepare low UV absorptive components using just a UV signal as the trigger, so there is a risk that the fraction will be missed. By using the MS signal as the trigger, the preparative work can be performed simply, with nothing missed. By specifying the m/z of the target component, fractions can be collected with confidence. The LCMS-2050 mass spectrometer enables high-sensitivity and high-resolution detection for preparative work with no target components omitted.

Purification of Un-separated Target Components

Two specific m/z values (from the target component and its impurity) were simultaneously used to obtain an “high-purity” fraction, even in the case of incomplete chromatographic separation.

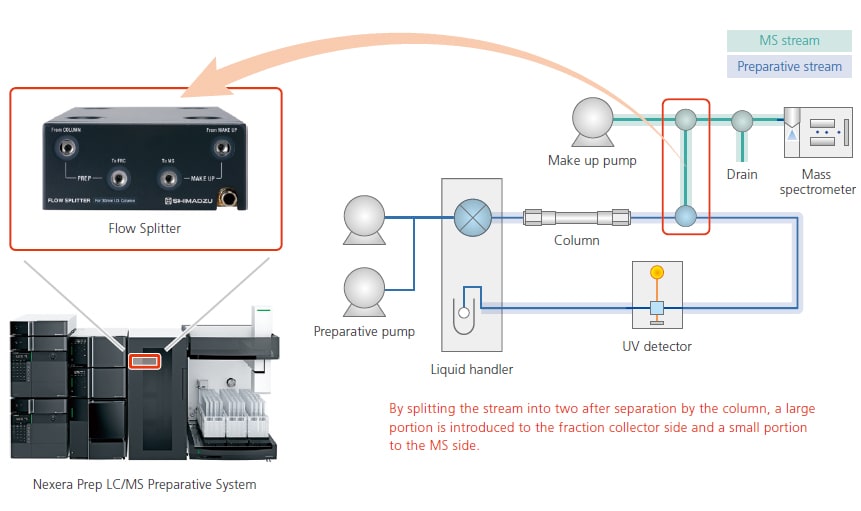

Flow Splitter for Fractionation Triggered by LC/MS Signals

For fractionation triggered by LC/MS signals, a portion of the sample must be introduced into the LC-MS.

The dedicated flow splitter splits a small portion of the flow from the preparative stream to the MS stream. This enables the use of LC-MS detection signals for triggering fractionation while maintaining a high recovery rate.

Customized Detection Methods

Signals from various detectors can be used for triggering the fractionation. The optimal system configuration can be obtained for different samples and conditions.

Increased Efficiency from Preparative Analysis Setup to Data Processing

Open Solution Software for Preparative Systems

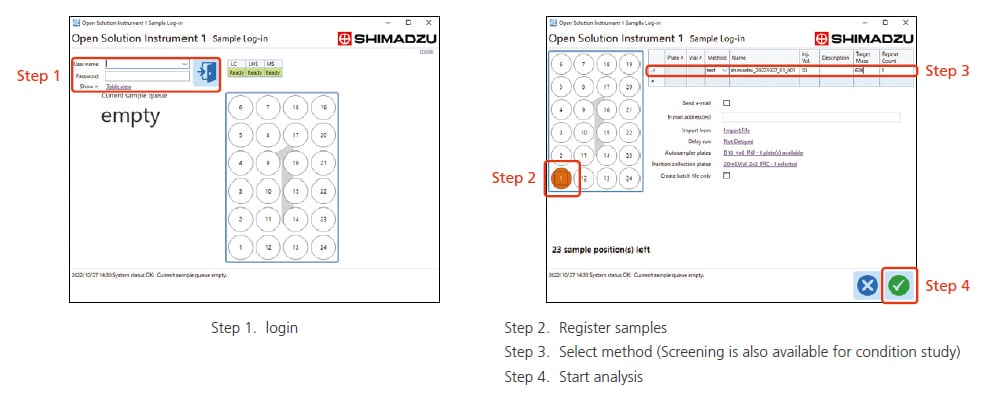

Open Solution is open access software that not only streamlines preparative purification operations, but also supports multi-user operation of preparative systems. Even inexperienced users can perform routine preparative operations easily with minimal efforts.

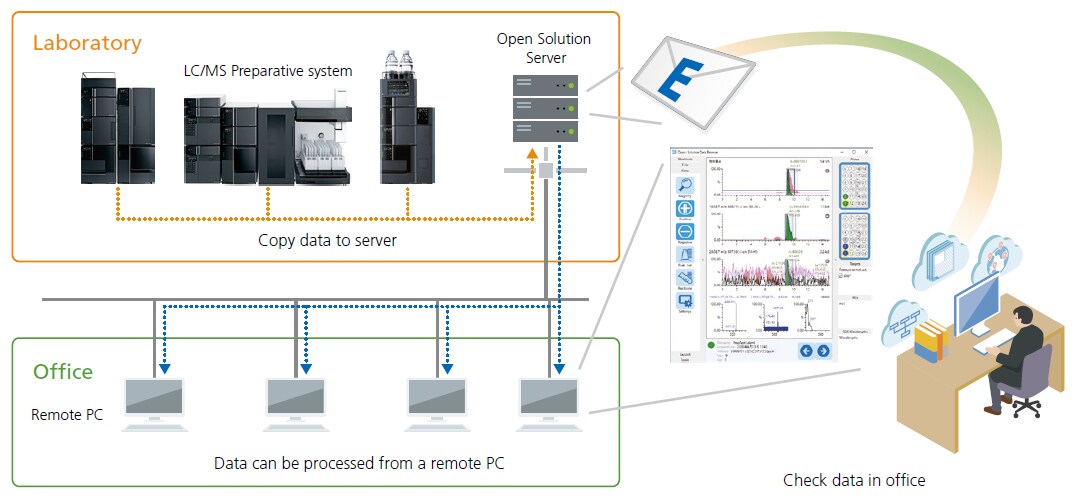

The use of a network contributes to improved work efficiency.OpenSolution

Easy Operation, Screening Using Multiple Conditions

After logging into Open Solution, analysis can be started from a single screen by simply selecting a pre-registered method and registering a sample. Screening analysis can be easily performed with the same procedure. While the system is performing an analysis, a different user can schedule the next analysis.

Open Solution software will automatically include washing steps between different user methods, reducing the system downtime.

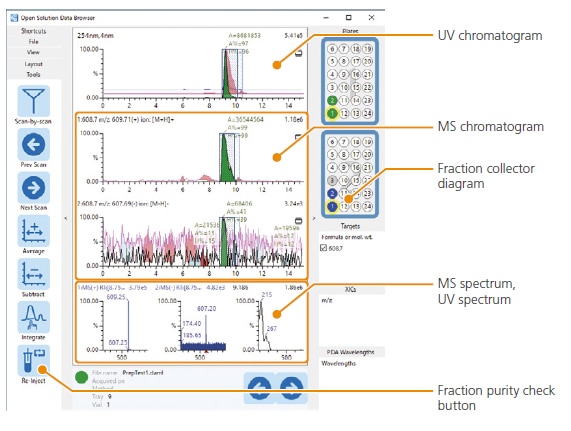

Confirmation of Fractionation and Re-injection Analysis

By selecting the vial displayed in the fraction collector diagram, the chromatogram, mass spectrum, and UV spectrum of that fraction can be easily confirmed. From the same screen, it is possible to directly check the purity of the fraction.

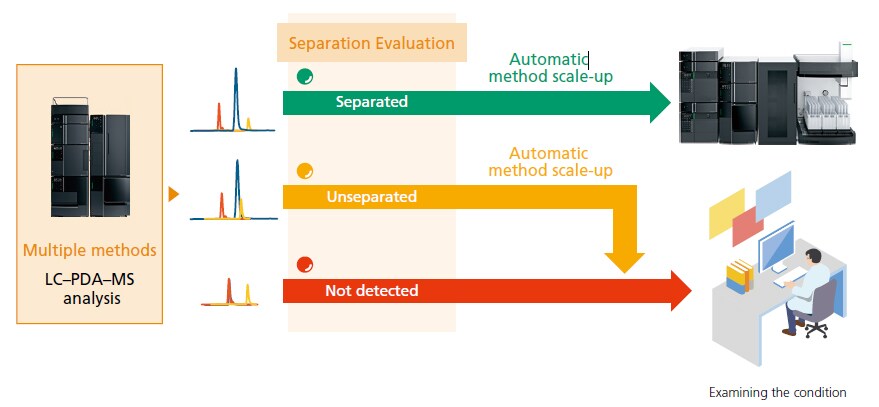

Automatic Scale-up from Analytical Scale to Preparative Scale

When screening analysis is performed to examine preparative conditions, the results are judged in three steps according to the degree of separation and MS spectral purity. If the judgment is acceptable, a preparative method is automatically generated. Therefore, the user can focus on examining conditions for samples with insufficient separation or aren’t detected.

Remote Data Processing

After data acquisition, the system sends an e-mail notification with a link to the data storage location and a report. Therefore, data processing can be performed immediately. In addition, data analysis can be performed from a remote PC by utilizing the network.

High Separation via Preparative Recycling

Components Difficult to Separate can be Recovered at High Purity Levels and at Low Cost

Recycling Preparative System

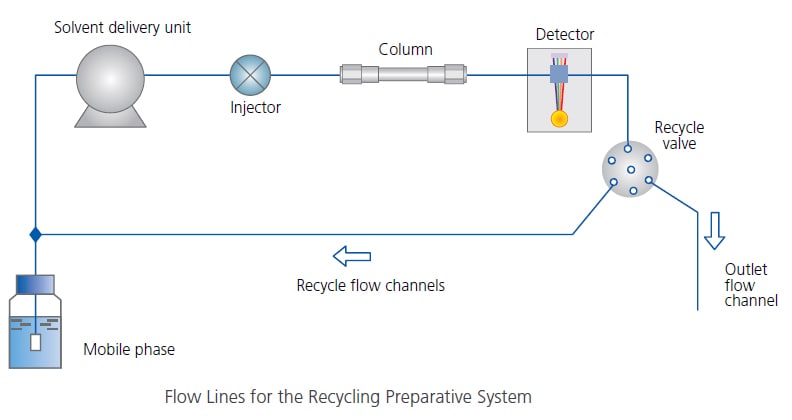

What is the recycling separation method?

Because long preparative columns are expensive, there is a need to use comparatively lower cost short columns.

In the recycling separation method (closed valve recycling), the eluate liquid containing the target components that has eluted from the separation column is recycled into the column, enabling an equivalent separation capacity to that of a longer column.

The figure below shows the results of a seven-cycle recycling separation. In the first injection (typical separation), the separation of the two components is insufficient (red area). However, when the column eluate is returned to the column from the detector, it is separated a second time. If this recycling is repeated, the results obtained are equivalent to connecting a number of columns in series corresponding to the number of repetitions. In this example, a 4.0 or better resolution was ultimately obtained with seven recycling separation cycles (blue area).

Example of the improvement in separation by recycling : The coeluting peaks (red) are completely separated (blue).

Flowrate : 10 mL/min

Detection wavelength : 254 nm

Column : Shim-pack PREP-ODS(H) 20 mm I.D. x 250 mm L.

Mobile phase : Water/methanol = 1/9 (v/v)

Sample : Mixed 1% n-butylbenzene/iso-butylbenzene solution

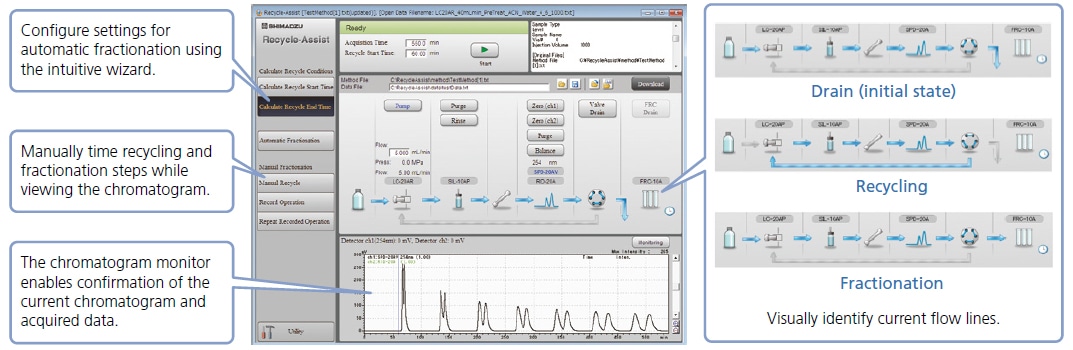

Recycle-Assist* – Special Preparative Recycling Software

Perform Automatic Preparative Recycling with a Simple GUI-Based Operating Environment

The graphical user interface (GUI) provides an environment where even novices to preparative recycling can perform operations simply and reliably. A single main window is used for the workflow from recycling to fractionation, thus reducing the risk of wasting precious samples through setting mistakes.

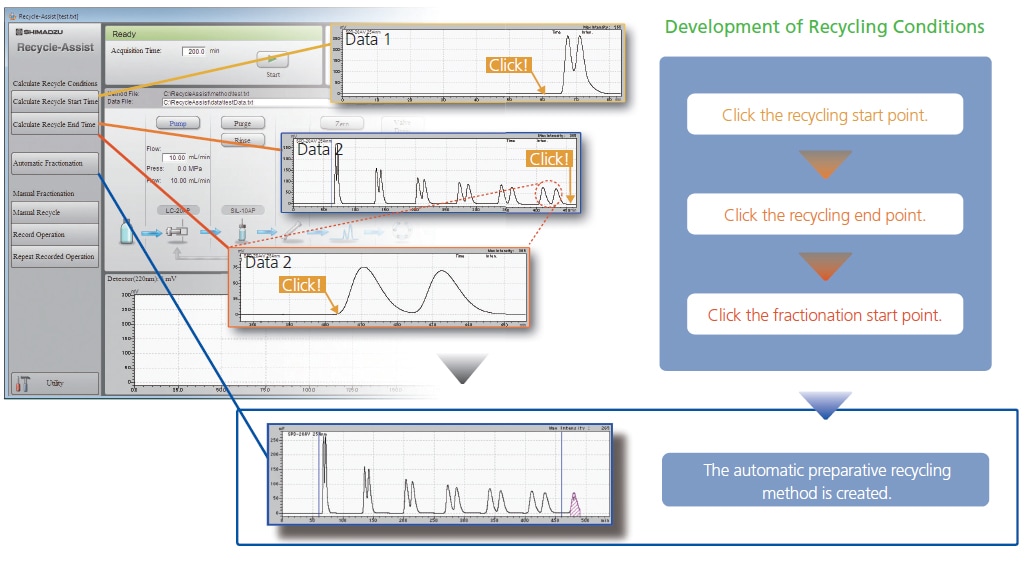

Recycling Conditions are Completely Set in Three Steps

Just click three points corresponding to the recycling start, recycling stop, and automatic collection start point to complete the settings for the recycling preparation conditions. Entering complicated numerical parameters is completely unnecessary, so recycling preparative work can start easily.

* This is compatible with the FRC-10A

Excellent System Expandability

System Configuration Applicable to a Variety of Applications

Solvent Delivery Unit Accommodates a Wide Range of Recovery Volumes

Solvent Delivery Unit Accommodates a Wide Range of Recovery VolumesShim-pack Scepter ColumnsThe LH-40 Liquid Handler, Combination of Autosampler and Fraction CollectorFRC-40, Highly Flexible Fraction Collector